Warehouse Management System

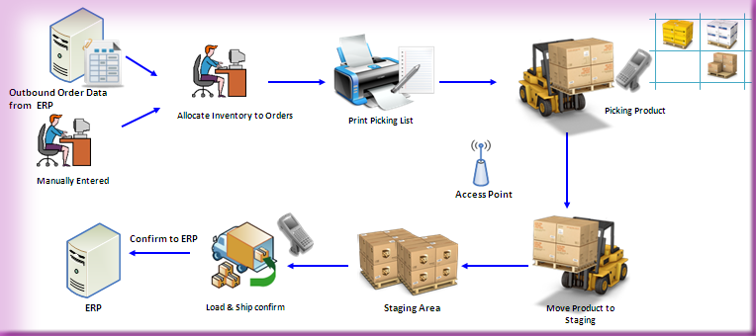

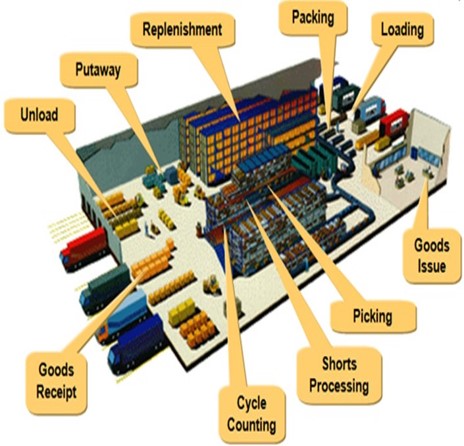

WMS is a warehouse management system. Which will have a management process ranging from goods to warehouses until leaving the warehouse Which the main process is to receive goods, store products and picking

- Goods receipt is the first process that occurs in the warehouse. Which when the product is brought to the warehouse. The warehouse staff will record the details of the product, which can be done by Manual, which is the information input to the system or will use the data interface to be used as the default. Which this interface Will save time in the input of information Which is the default setting, data may be imported from the PO from an accounting program or other information such as ASN Advance Ship Notice or will be imported from EDI

- Product storage Is a continuous process from receiving. The warehouse staff can use WMS to find the appropriate storage location. Which the system will help to think that Where there is space and where it should be stored, which WMS will help keep the product accurate and can calculate the space in the warehouse

- Picking Is the process of bringing products out by the WMS system with conditions that help find products faster and more accurately for example some products require the correct lot

How the Warehouse Management System (WMS) helps solve the problem?

1. Receiving Process: The WMS system can reserve space or reserve space in advance to help plan the use of space in the warehouse effectively because some warehouses without good systems. When receiving the goods into the warehouse, it will be taken as you like. Finally, I can't remember where to store it.

2. Put Away Process: The WMS system can recommend suitable locations for storage. And confirmed the correct storage location Manual: by the inspector signed After checking that it is actually stored in that location Barcode Scanner: by shooting the Barcode Scanner in the actual storage location This will help to confirm the storage location correctly, which will help reduce the problem of finding products.

3. Picking process: WMS system will have a search system to help search easily, just fill out the conditions. The system can search for products for themselves. Whether it's FIFO, LIFO, FEFO or can be customized

Does the warehouse need to use WMS?

"Every warehouse doesn't need to use WMS." But what is certain is that If any warehouse is used, WMS must definitely benefit from using software such as Reducing the number of inventories Reducing the use of workers Increasing utilization of storage space Increase the speed of customer service and finally, to increase the accuracy of the inventory system

Benefits from WMS

- improve the potential speed and error reduction

- Accurate in dealing with warehouse systems

- Reduce working time in organizing space

- The most cost-effective space

- Reduce product backlog

- Control various work processes

- Daily operation (Daily Operation)

- Inventory Control and Analysis

- Accounting and finance (for 3pl)